EN-B ::: LIGHTNING

MORE PERFORMANCE WITH LESS WEIGHT

Based on the successful XC machine the Blacklight, U-Turn has designed a lightweight wing with stunning comfort and performance. The LIGHTNING is for ambitious pilots who want to go XC with ease – without sacrificing comfort. With the intelligent choice of light weight material a significant weight and drag reduction has been reached. That raised the overall performance- in particular the glide with a remarkable 10.5. The lighter canopy has a positive effect to the flying characteristic in turbulent air – the wing stays calm and balances quickly the pressure differences. But not only in flight has the light weight design come into effect, it eases the comfortable inflation handling too, in special under difficult conditions.

The LIGHTNING is the response to the rapidly growing demand to light weight XC wings. The Focus was set to the comfort flying the wing, spite it is already optimized regarding packing volume and

weight; it should feel like a “full” wing. But comfort too in the sense of passive safety. The LIGHTNING fulfills the demands to the EN/LTF B class with ease. The main principle of U-turn - safety

and performance - was implemented here with consequence.

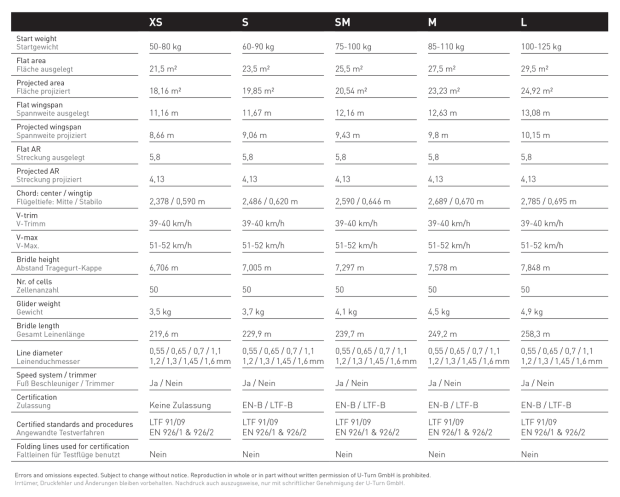

U-Turn chief designer Ernst Strobl gave the Lightning 50 cells and a flat aspect ratio by 5.8. The wing is mainly made out of Skytex 27, only in the more stressed leading edge Skytex 36 is

used. The ribs and the V-ribbs are made of Skytex 27 hardfinish. The LIGHTNING has 2A, 3B, and 2C main lines. The used lines are mostly unsheathed Kevlar lines in 8 different diameters to receive a

balanced line loading. This leads naturally to reduced weight and drag.

The LIGHTNING is the first wing in the new U-Turn design. The new line accents the technical design and the aspect ratio. The theme in the redesign was to connect the U -Turn roots to a clearer

design line. The new design fills functional demands too; the new line allows an optimal material mixture in the higher loaded areas.

The LIGHTNING is now available in 4 sizes certified to EN/LTF B: Lightning S (60 – 90 kg), Lightning SM (75 – 100 kg), Lightning M (85 – 110 kg), Lightning L (100 – 125 kg).

Get your own experience, how easy the stunning performance of the LIGHTNING handles.

The LIGHTNING is equipped with the High Definition Profile (HDP). Small plastic reinforcements

in the topsail from 45 to 80% of the profile depth make a wrinkleless profile line and a good flow along the profile.

The Precision Profile Nose (PPN) enhances the geometry and stability and hereby the flow around

the whole leading edge.

The High Pressure Crossport Design (HPCD) ensures perfect cross ventilation and balances pressure

differences in the canopy and keeps it on a high level. Thus the wing recovers quickly after a collapse -smaller ones can even be prevented.The line to line connections are equipped with the Line

Loop Protection (LLP) to prevent the line loops from breaking under peak loads. Therfor a kevlar core is spliced in the line to prevent a tangling of the line loops to other

lines.

Nos coordonnées :

Dezair Sarl

20 Route d'Ombre

Marlens

74210 Val de Chaise

Téléphone : 04.50.32.85.85

e-mail: info@dezair.com

Horaires d'ouverture

Lundi au Vendredi

8h00-12h00 / 14h00-18h00

Samedi, Dimanche

sur rdv